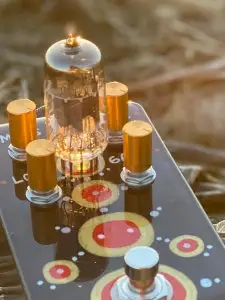

Once pivotal in the evolution of electronics, vacuum tubes continue to play a significant role in modern technology, particularly when it comes to music. These fascinating components, which were instrumental in the early development of amplifiers, radios, televisions, and the first computers, have found enduring relevance in today’s world. Their unique sound quality and distinct characteristics make them highly sought after in guitar amplifiers and HiFi systems, where they are celebrated for their warm and rich tonal properties. This blog post will explore the ongoing production of vacuum tubes, focusing on their contemporary applications, especially in music and audio fidelity. We will delve into the global production landscape, comparing the enduring charm of vintage tubes with the perceived challenges and qualities of their modern counterparts.

Are Vacuum Tubes Still Made?

In the era of advanced solid-state electronics, it might come as a surprise to many that vacuum tubes are not only still made, but also actively used and manufactured across the globe. Their continued production is driven by a persistent demand in specific sectors such as audio engineering, where the warmth and richness of tube-generated sound is unmatched. However, the landscape of vacuum tube manufacturing has changed significantly over the years. No longer a mainstream necessity, these components are now produced in much smaller quantities, catering to a niche market. This shift has had profound implications on the manufacturing process, quality control, and the economics of vacuum tube production.

Challenges and Concerns in Modern Vacuum Tube Production

The modern production of vacuum tubes is fraught with challenges, often leading to questions about their reliability and longevity. Unlike their robust and enduring vintage predecessors, contemporary tubes frequently face criticism for being manufactured with cost-cutting measures in mind. This approach can result in tubes that are prone to failure, causing frustration among users who rely on them for high-quality audio in guitar amps and HiFi systems. The production process itself is complex and toxic, governed by stringent regulations and requiring skilled labor. These factors contribute to the high costs and difficulties in manufacturing quality tubes. Moreover, the niche market for vacuum tubes means that production volumes are relatively low. As a result, some manufacturers opt to produce these components in regions where labor costs are lower, which raises concerns about labor exploitation and the ethical implications of such practices. This stark contrast with the golden era of tube manufacturing highlights not only the technological but also the socio-economic shifts in this specialized industry.

Russia:

Russia remains a significant player in the vacuum tube market with companies like Sovtek and New Sensor Corporation at the forefront. Sovtek is particularly noted for its wide range of tubes used in various applications, including audio and guitar amplifiers. New Sensor Corporation, another key manufacturer, continues the legacy of Russian tube production, maintaining production facilities that have been operational since the Soviet era. These companies represent the enduring presence of Russian-made vacuum tubes in the global market.

China:

In China, Shuguang and Psvane are among the major manufacturers in the vacuum tube industry. Shuguang, established over several decades ago, has grown to become one of the largest tube producers worldwide. Psvane, another significant player, specializes in high-end tubes and has gained recognition in various markets. Chinese manufacturers have expanded their presence significantly, catering to both domestic and international demands for vacuum tubes, especially in consumer electronics and audio applications.

Slovakia:

Slovakia’s contribution to the vacuum tube industry is marked by companies like JJ Electronic. JJ Electronic is particularly known for its range of tubes used in audio and guitar amplifiers. The company’s focus on maintaining a consistent production line has allowed it to establish a presence in the international market. Slovakian tubes, produced by these manufacturers, are part of the smaller but important European segment of the vacuum tube industry. Of the modern tube companies, JJ is most respectable. Slovakia has more stringent labor laws and safety regulations. Moreover, their tubes are higher quality.

The Appeal of Vintage Tubes

Vintage vacuum tubes, revered for their unmatched quality and unique sound characteristics, also carry the appeal of being products of skilled craftsmanship. Originating from an era when meticulous attention to detail was the norm in manufacturing, these tubes are lauded for their robustness and longevity, outshining many modern counterparts. The use of these tubes today is a nod to sustainable practices, as it promotes the reuse of well-made, durable items, reducing the need for new production.

Sound-wise, vintage tubes are celebrated for their warm, rich tonality, offering a depth and organic feel that many enthusiasts and professionals find lacking in modern tubes. This distinctive sound, highly sought after in audio and musical applications, stems from their superior build quality and the advanced manufacturing techniques of the past.

Moreover, vintage tubes are reminders of a time when labor in manufacturing was often valued differently, with a focus on skill and craftsmanship. This aspect is increasingly important to consumers who seek products with ethical and historical significance. In sum, the appeal of vintage tubes lies in their durability, exceptional sound quality, and the craftsmanship they represent, making them a cherished choice in the world of audio and music.

Conclusion

In closing, vacuum tubes are a fascinating blend of past and present. Modern production continues in Russia, China, and Slovakia, yet it’s the vintage tubes, with their superior quality and rich sound, that steal the spotlight. These older tubes not only outshine in durability and performance but also represent an era of skilled craftsmanship and fair labor practices, a stark contrast to some of today’s manufacturing norms. So, as we embrace these electronic antiques, we’re also valuing a legacy of quality and ethical craftsmanship.